Weinig Hydromat 1000 metal milling machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

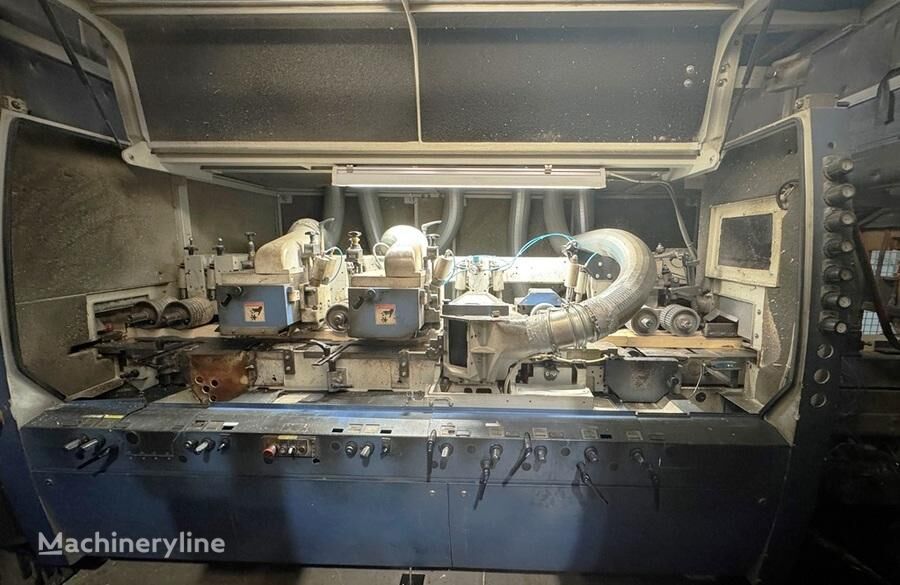

Automatic planer and moulder WEINIG Hydromat 1000

Used, year of construction 2007

6 spindles: bottom-right-left-top-top-bottom

Electronic feed 6 - 60 m/min

Working width 80 - 150 mm

Working height 23 - 65 mm

Finished slat widths 4 - 15 mm

Max. number of slats 16 pieces

Slat lengths 400 - 4000 mm

1st spindle horizontal at the bottom

Brake motor 11 kW, 6000 rpm

Spindle diameter 45 mm

Tool flight circle 125 - 180 mm

2nd spindle vertical right

Brake motor 7.5 kW, 6000 rpm

Diameter 45 mm

Tool flight circle 112 - 250 mm

Max. Moulding depth 35 mm

Axial adjustment travel 80 mm

3. spindle vertical left

7.5 kW, 6000 rpm

Diameter 45 mm

Tool flight circle 112 - 250 mm

Max. Moulding depth 35 mm

Axial adjustment travel 80 mm

Pressure shoe in front of the spindle, swiveling away, pneumatic roller contact pressure

4. spindle horizontal top

15 kW, 6000 rpm, diameter 45 mm

Tool flight circle 112 - 250 mm

Max. Moulding depth 35 mm

Axial adjustment path 45 mm

Split pressure shoe in front of upper spindle, adjustable and swiveling away, pneumatic

5. horizontal top spindle as saw spindle

Brake motor 37 kW, 5000 rpm

Diameter 45 mm

Axial adjustment travel reduced to 25 mm

Tool flight circle 112 - 250 mm

Max. Sawing depth 35 mm

Axial adjustment path 45 mm

Split pressure shoe in front of upper spindle, adjustable and swiveling away, pneumatic

6. horizontal spindle at the bottom as saw spindle

Brake motor 30 kW, 5000 rpm

Axial adjustment travel reduced to 25 mm

Diameter 45 mm

Tool flight circle 112 - 250 mm

Max. Sawing depth 35 mm

Axial adjustment path 45 mm

All moulder spindles with high-performance bearings

Electronic feed 7.5 kW

Adjustment travel of the feed rollers compared to the left-hand spindle, axial 35 mm

Shorter roller distance compared to the right-hand spindles

Running meter counter, electric, with 2 counters

Short infeed table (1.2 m) with 2 driven rollers above the table

1 driven, toothed roller in the table, lateral pressure roller

Automatic waxilite pump / lubricant pump

Machine with 4-roller extension, pendulum shafts extended to 200 mm

2 driven, toothed rollers in the outfeed table

2 driven, toothed rollers in the machine table

Pressure beam before and after upper spindle with mechanical digital display

DigiSet (digital double display) for left and top spindles

Electrical height adjustment of the upper spindles and the feed

Machine already dismantled and stored

Sale on behalf of customer, ex location near South Tyrol, without transportation and assembly

Subject to errors in the description and price

Transportation and loading by us optionally possible

To avoid possible misunderstandings, an on-site inspection by appointment is possible and recommended

Sold as is

Technical details, condition description, year of construction and scope of delivery according to manufacturer's brochure or previous owner, without guarantee

Subject to prior sale

For used machines, any warranty is excluded, the following applies: “purchased as seen”

Images and videos serve as examples and do not represent the actual scope of delivery

Terms of payment: Prices plus VAT, payment before collection or dispatch

Terms of delivery: ex location

Our general terms and conditions apply, available on the Internet at

show contacts

Please pay particular attention to Article 9 regarding complaints and returns!